半尿細管リベット

You can purchase Semi Tubular Rivets from Notin with confidence, as we are a proficient producer of high-quality Semi Tubular Rivets. We promise to provide you with the best after-sale service and prompt delivery.

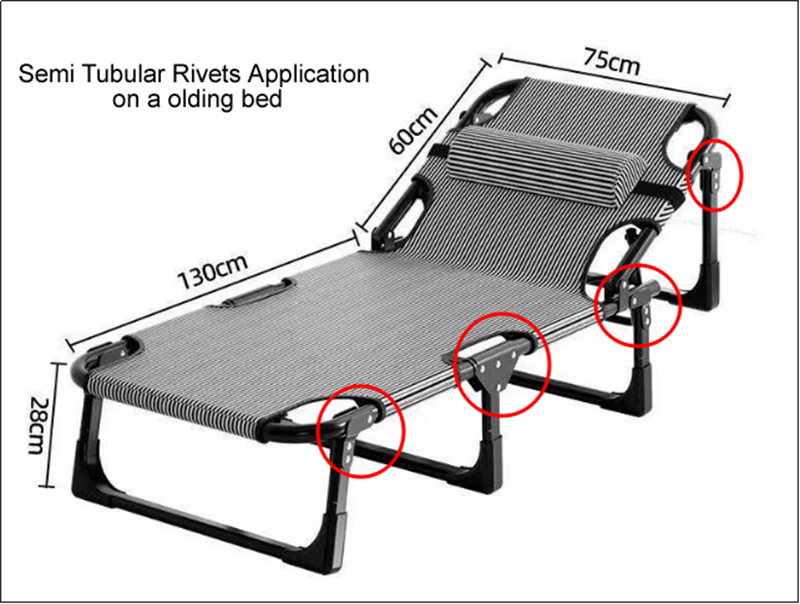

Semi-tubular rivets are a common mechanical fastener widely used in industrial manufacturing, electronic equipment, automotive parts, and other fields. Their structure lies somewhere between solid and hollow rivets, with a solid head and a hollow tail, combining the advantages of both. The following analyzes the characteristics of semi-tubular rivets and their differences from other rivets from various perspectives.

What are semi-tubular rivets?

Semi-tubular rivets typically have a solid cylindrical or round head and a hollow tubular tail. During installation, pressure is applied to the tail using a riveting tool, causing it to curl outward and form a secure locking structure. This process requires no pre-tapping or welding, making it suitable for quick assembly. In contrast, solid rivets require greater pressure to deform, while fully hollow rivets (such as blind rivets) rely on the mandrel to break to secure, requiring higher material strength.

What head shapes are available for semi-tubular rivets?

Semi-tubular rivet head shapes generally include flat heads (flat heads, suitable for applications requiring smooth surfaces), domed heads (semi-circular heads, aesthetically pleasing and practical, commonly used in construction, automotive, and other fields), countersunk heads (heads embedded within the material, suitable for applications requiring concealed connections), and large flat heads. Different head shapes can be selected based on your needs.

Materials and Strength of Semi-tubular Rivets

Common materials for semi-tubular rivets include aluminum, copper, steel, and stainless steel. Aluminum rivets are lightweight and corrosion-resistant, making them suitable for electronic devices; steel rivets are stronger and are often used in load-bearing structures. Compared to solid rivets, semi-tubular rivets are lighter but have slightly lower shear strength. Compared to full tubular rivets, their curled tails provide a larger contact area, resulting in a more stable connection.

What are semi tubular rivets primarily used for?

Typical uses for semi-tubular rivets include:

-Automotive manufacturing: securing interior panels or wiring harness brackets to prevent loosening under vibration.

-Home appliance assembly: connecting metal casings to prevent deformation caused by welding. -Hardware Tools: Assemble movable parts such as pliers and scissors, ensuring a balance between flexibility and durability.

Semi Tubular Rivet Installation Cost

Semi-tubular rivets can be installed with a standard rivet gun or punch, and can be operated by a single person. They are faster than welding or bolting. For example, the cost per aluminum rivet is approximately 0.05-0.3 RMB, which is lower than stainless steel bolts but higher than ordinary blind rivets. Their advantage is that they require no maintenance over long-term use, eliminating the need for anti-loosening washers or regular tightening.

Limitations of Semi Tubular Rivets

The main disadvantages of semi-tubular rivets are:

-Difficulty in Disassembly: Once a joint is established, it requires multiple drilling and destruction methods to remove it.

-Thickness Limitation: The total thickness of the joined materials is generally no more than twice the length of the hollow portion of the rivet.

-Surface Treatment Requirements: For outdoor use, choose galvanized or stainless steel to prevent rust.

Comparison with Other Fasteners

-Bolts and Nuts: They are removable and have a higher load-bearing capacity, but require access from both sides and are more expensive. - Welding: Excellent connection strength, but thermal deformation may affect precision, and it's not suitable for materials like aluminum and copper.

- Adhesives: No mechanical stress, but poor high-temperature resistance and aging resistance.

In summary, semi-tubular rivets strike a balance between lightweight, easy installation, and cost, making them particularly suitable for specialized connections with medium loads. When selecting a rivet, consider material compatibility, environmental conditions, and load-bearing requirements to ensure a suitable match.

- View as

なべ半中空リベット

当社のなべ頭半中空リベットがどのように作られているのか不思議に思ったことはありませんか?以下に簡単な手順を示します。

まず、適切な金属ワイヤーを選択し、必要な正確な長さに切断します。次に、冷間圧造機に移り、ワイヤーを打ち抜いて基本的なリベット形状に成形します。ここで、なべ頭と中空シャンクが実際に形成されます。次は熱処理です。材料に基づいて時間と温度を微調整し、すべてのリベットが適切な強度と靭性を持っていることを確認します。その後、錆を防ぎ長持ちさせるために、亜鉛メッキや不動態化などの保護仕上げを追加することがよくあります。そして、最終チェックを省略することはありません。各バッチを検査して、サイズ、仕上げ、性能が標準に達していることを確認します。

私たちはいつでも喜んでお客様をご案内します。この地域にお越しの際は、ぜひお知らせください。ツアーを手配します。

マッシュルームヘッド半中空リベット

マッシュルームヘッド半中空リベットは、部分的に中空のシャンクと組み合わせられた、キノコの傘に少し似た独特のドーム型のヘッドにその名前が付けられています。このデザインにより、取り付け中にリベット自体が形を整え、強力な保持力が得られます。見栄えと確かな性能の両方が必要な用途に最適です。セットすると、中空の端が広がってしっかりとグリップし、ヘッドとシャンクの上部セクションはしっかりとしたままでサポート力が高まります。

続きを読むお問い合わせを送信