半尿細管リベット

You can purchase Semi Tubular Rivets from Notin with confidence, as we are a proficient producer of high-quality Semi Tubular Rivets. We promise to provide you with the best after-sale service and prompt delivery.

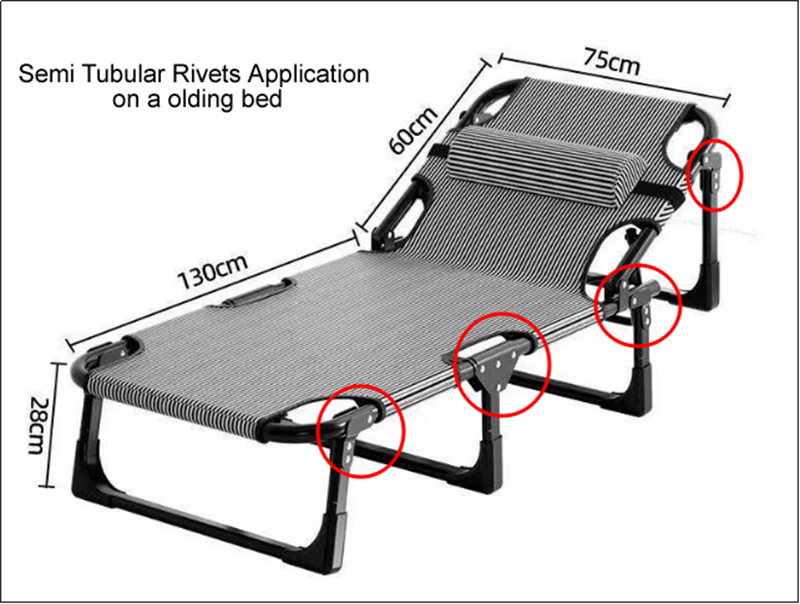

Semi-tubular rivets are a common mechanical fastener widely used in industrial manufacturing, electronic equipment, automotive parts, and other fields. Their structure lies somewhere between solid and hollow rivets, with a solid head and a hollow tail, combining the advantages of both. The following analyzes the characteristics of semi-tubular rivets and their differences from other rivets from various perspectives.

What are semi-tubular rivets?

Semi-tubular rivets typically have a solid cylindrical or round head and a hollow tubular tail. During installation, pressure is applied to the tail using a riveting tool, causing it to curl outward and form a secure locking structure. This process requires no pre-tapping or welding, making it suitable for quick assembly. In contrast, solid rivets require greater pressure to deform, while fully hollow rivets (such as blind rivets) rely on the mandrel to break to secure, requiring higher material strength.

What head shapes are available for semi-tubular rivets?

Semi-tubular rivet head shapes generally include flat heads (flat heads, suitable for applications requiring smooth surfaces), domed heads (semi-circular heads, aesthetically pleasing and practical, commonly used in construction, automotive, and other fields), countersunk heads (heads embedded within the material, suitable for applications requiring concealed connections), and large flat heads. Different head shapes can be selected based on your needs.

Materials and Strength of Semi-tubular Rivets

Common materials for semi-tubular rivets include aluminum, copper, steel, and stainless steel. Aluminum rivets are lightweight and corrosion-resistant, making them suitable for electronic devices; steel rivets are stronger and are often used in load-bearing structures. Compared to solid rivets, semi-tubular rivets are lighter but have slightly lower shear strength. Compared to full tubular rivets, their curled tails provide a larger contact area, resulting in a more stable connection.

What are semi tubular rivets primarily used for?

Typical uses for semi-tubular rivets include:

-Automotive manufacturing: securing interior panels or wiring harness brackets to prevent loosening under vibration.

-Home appliance assembly: connecting metal casings to prevent deformation caused by welding. -Hardware Tools: Assemble movable parts such as pliers and scissors, ensuring a balance between flexibility and durability.

Semi Tubular Rivet Installation Cost

Semi-tubular rivets can be installed with a standard rivet gun or punch, and can be operated by a single person. They are faster than welding or bolting. For example, the cost per aluminum rivet is approximately 0.05-0.3 RMB, which is lower than stainless steel bolts but higher than ordinary blind rivets. Their advantage is that they require no maintenance over long-term use, eliminating the need for anti-loosening washers or regular tightening.

Limitations of Semi Tubular Rivets

The main disadvantages of semi-tubular rivets are:

-Difficulty in Disassembly: Once a joint is established, it requires multiple drilling and destruction methods to remove it.

-Thickness Limitation: The total thickness of the joined materials is generally no more than twice the length of the hollow portion of the rivet.

-Surface Treatment Requirements: For outdoor use, choose galvanized or stainless steel to prevent rust.

Comparison with Other Fasteners

-Bolts and Nuts: They are removable and have a higher load-bearing capacity, but require access from both sides and are more expensive. - Welding: Excellent connection strength, but thermal deformation may affect precision, and it's not suitable for materials like aluminum and copper.

- Adhesives: No mechanical stress, but poor high-temperature resistance and aging resistance.

In summary, semi-tubular rivets strike a balance between lightweight, easy installation, and cost, making them particularly suitable for specialized connections with medium loads. When selecting a rivet, consider material compatibility, environmental conditions, and load-bearing requirements to ensure a suitable match.

- View as

銅製半中空リベット

銅はご存知の通り、優れた電気伝導性と熱伝導性が必要なときに絶対に期待を裏切らない信頼できる素材です。だからこそ、銅の半中空リベットが非常に確実な選択肢となるのです。銅の自然な強みと、仕事を完璧にこなす賢い半中空のデザインを組み合わせたものです。 Nuote Metals では、これが当社の専門分野です。当社は、ますます多くの産業用途に登場し続けているこれらの多用途銅リベットの信頼できる供給源となっています。私たちのチームには、10 年以上リベットを製造してきたエンジニアが数名います。私たちは自分たちの仕事に真の誇りを持っています。金型の設計から完成品に至るまで、すべてのリベットに細心の注意が払われています。私たちはあらゆる細部を正確に仕上げることにかなりこだわっています。

続きを読むお問い合わせを送信真鍮半管状リベット

真鍮の半管状リベット - 半分くらいまで中空の芯がある信頼できる金属製の留め具のようなものです。基本的には銅と亜鉛の混合物である真鍮から製造しています。真鍮の優れている点は、錆びにくく、激しい衝撃にも耐えられることです。だからこそ、この小さな主力製品はどこにでもあるのです。これらのリベットの 1 つをよく見てみると、2 つの単純な部分が見えます。上部にあるヘッドと、結合しているものを突き刺すシャンクです。ここが賢い部分です - シャンクの中空の中心です。リベットを固定すると、底が広がってしっかりとグリップします。一度入ってしまうと、もうどこにも行きません。

続きを読むお問い合わせを送信アルミ半中空リベット

アルミニウム半中空リベットは、基本的にアルミニウム合金で作られた締結具です。頭はしっかりしていて、尾は部分的に空洞になっています。特別なツールを使用してそれらを取り付けると、その中空部分が広がってカールし、非常に強力で固定された接合部が形成されます。アルミなので当然軽くて錆びにくいので、重さが気になる場合やハードな環境で使用する場合には大きなメリットとなります。他の素材で作られたリベットと重ね合わせると、手頃な価格と優れたパフォーマンスの間の最適な場所に到達します。

続きを読むお問い合わせを送信